Sleeves For Custom Packaging Can Make Your Product Look Better

Custom-printed sleeves are a great option if you’re looking for an effective way to take your product packaging to the next level. These adjustable sleeves can add a layer of protection to a wide range of products.

Sleeves Packaging Tailored To Your Specific Needs

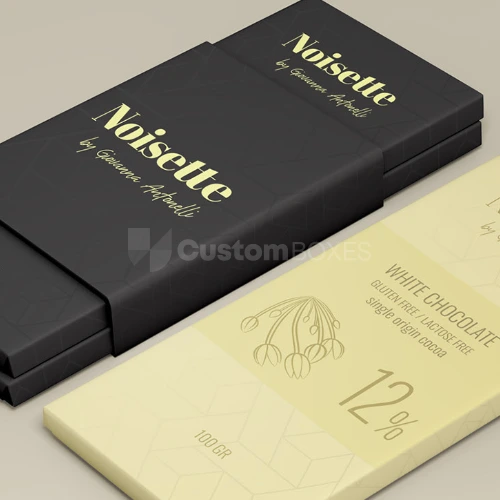

We at U Custom Boxes are experts at making custom sleeves packaging that fits your needs and tastes perfectly. We offer a variety of materials, finishes, and customization options to ensure that our sleeve packaging perfectly suits your brand and product. Our sleeves are made of high-quality, environmentally friendly materials meant to last and look good. Custom packaging sleeves can be made to your specifications.

Sleeve Packaging To Draw In Customers

Putting money into custom sleeve packaging can make a big difference in how your customers see your products. With our help, you can create packaging for your products that looks great, protects them, and makes them more appealing. Contact us now to learn more about our sleeve packaging alternatives and how they might benefit your company.

Sleeves Box Packaging-Provide Extra Protection

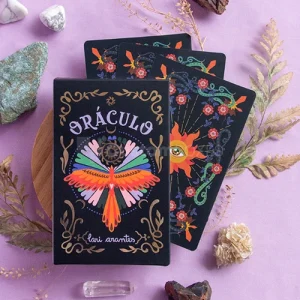

Sleeve box packaging can help your food, beauty, or tech products stand out and attract more customers. It improves product presentation. It is a great way to make your products look better and give them more protection at the same time.

Box Sleeve Packaging & Plastic Sleeve Packaging

Our company provides a variety of box sleeves packaging options, such as cardboard packaging sleeves and plastic packaging sleeves, to meet your needs. These sleeves can be made to your size, shape, and design specifications to create a distinctive, eye-catching product packaging solution.

Whether you are looking for a sleek and modern design or more traditional cardboard packaging sleeves, we can help you. So, create the perfect packaging solution to fit your brand and product.

Grow Your Brand With Custom Box Packaging Sleeves

Packaging sleeves for boxes are an excellent way to add protection to your products while also enhancing their visual appeal. Furthermore, our company creates custom packaging sleeves tailored to your needs and reference packaging sleeve printing for vibrant and long-lasting designs.

Our packaging sleeve printing process uses high-quality materials to create dynamic, durable designs. Custom packaging sleeve

We can also help you make the perfect custom packaging sleeve to fit your needs.

Why U Custom Boxes?

At U custom boxes, we believe in honesty and giving you unique packaging solutions that fit your needs. Our skilled team of professionals only uses the best materials to make custom packaging to help your brand stand out. Improve your packaging with a free personalized quotation now. In addition, we offer various packaging services, including Bag toppers, Packaging sleeves, and Packaging tapes, all made from the finest quality materials.